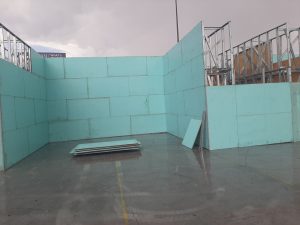

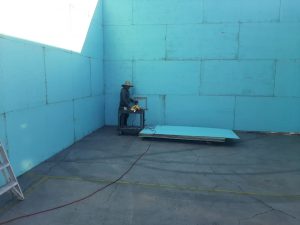

The tournament venue for our 3WallBall World Outdoor Championships is truly unique. Every year, the 3WB Build Team spends upwards of two weeks building and dressing the court complex in preparation for the event. They spend another week after the event disassembling the complex and returning the materials to storage.

All of this construction work is done largely behind the scenes. The courts are essentially ready for use by the time our players arrive, and our players are mostly gone by the time the Build Team descends back onto the complex to begin disassembly.

One thing that all of us at 3WB know is that Mike is not an “I” guy. He is always the first to downplay his individual contributions, and he takes pride in celebrating the success of the 3WB Team that he has put together.

This year — the 14th year of the 3WB World Outdoor Championships — we decided to highlight all of the behind-the-scenes work that the 3WB Build Team does by featuring information about the construction project on our social media platforms. We’ve summarized that information on this page to act as a tribute to the Build Team and to celebrate our unique 3WB Walls.

The 3WB Build Team

- The 3WB Build Team of 10-15 guys will spend a minimum of 12,000 man-hours building the court complex. This build typically lasts between 10 and 14 days, with the exact duration of the build depending on heat, wind, rain, and other variables.

- The Build Team will then spend an additional 20-30 man-hours ‘dressing’ the court — assembling booths, putting up tents, hanging banners, and building the VIP area. This activity typically takes between 2 and 3 days.

- During the build, the Build Team will drink 30-40 cases — that is, between 1,080 and 1,440 bottles — of water. These bottles (as well as many of the bottles and aluminum cans from the tournament) are collected for recycling. 80 pounds of ice a day — or 800 to 1,120 pounds in total — will be used during the build as well.

- 3WB buys the Build Team lunch every day — 10 pizzas one day, 30 tacos the next, 15 burgers the next, etc.

- After spending an exhausting 8 and 10 hours a day building the courts, Mike then goes shopping for a couple of hours to get supplies for the next day. He will average only 4-5 hours of sleep per night during the 10-14 days of the build.

The Courts

- The walls are made of ¾ in. ACX plywood, 10-20% of which is replaced every year.

- The plywood is affixed to 18 gauge galvanized wall studs. A 3-wall court contains 1,536 feet of studs. A 1-wall court contains 512 feet of studs. Factoring in the stud x-bracing adds another 64 feet of studs per court. All told, a court complex with 10 3-wall courts and 5 1-wall courts will contain 17,856 linear feet — or 3.4 miles — of studs.

- Self-tapping screws are used to affix the plywood to the studs. A 3-wall court contains between 960 and 1,280 screws. A 1-wall court contains between 300 and 400 screws. Every end cap contains 240 screws, and the stud x-bracing will use an additional 2,000 screws across the complex. In total, between 17,900 and 20,800 screws hold our walls together. If it takes an average of 2 seconds to drive each screw, the Build Team will spend between 10 and 12 man-hours just driving screws.

- The walls take between 20 and 30 5-gallon buckets — or between 100 and 150 gallons — of paint. The court floors are completely redone with new paint and new lines every year. All of the new plywood gets a coat of blue, and the reused plywood is touched up as needed.

- A 3-wall court is composed of 5,000 pounds of construction material. A 1-wall court is composed of 2,000 pounds of construction material. With 10 3-wall courts and 5 1-wall courts, we have 60,000 pounds of just construction materials on the court complex.

- 50-gallon barrels of water are used to weigh the courts down. Each barrel weighs 400 pounds, and there are between 50 and 75 barrels on site. Adding this 20,000 to 30,000 pounds of water weight to the weight of the court construction materials means that we have a minimum of 80,000 pounds — or 40 tons — of material on the court complex.

The 2023 Build

The following galleries document the day by day progress of the 2023 build and tear down.

Use the arrows to scroll through the photos. Click on a photo to open the gallery in a lightbox.